Horizontal Corner Spout Doypack Packing Machine

Category:

Horizontal Corner Spout Stand up Packing Machine can automatic bagging, filling, nozzle addition, nozzle welding, sealing. It's packing beverages, sauces

- Product Description

-

- Commodity name: Horizontal Corner Spout Doypack Packing Machine

- Commodity ID: HC-180SP ; HC-240SP

Horizontal Corner Spout Stand up Packing Machine can automatic bagging, filling, nozzle addition, nozzle welding, sealing. It's packing beverages, sauces

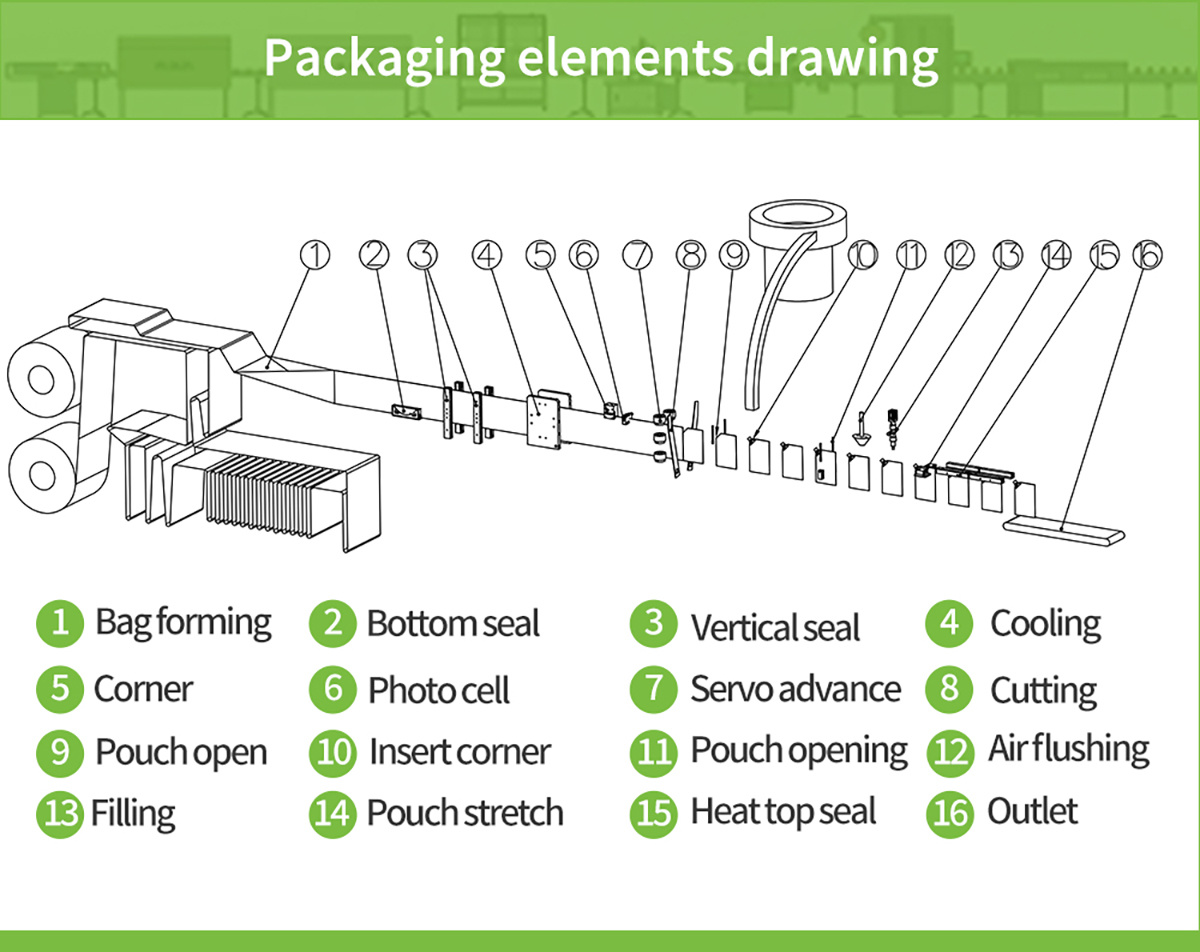

This machine can realize the packaging needs of oblique suction nozzle bags, and can also add hanging holes, special shapes, zippers, suction nozzles and other functions, realizing automatic bagging, automatic filling, automatic nozzle addition, automatic nozzle welding, and automatic sealing. It is used in the packaging of salt, lubricating oil, beverages, juice, yogurt, sauces, edible oil, and cleaning series.

Technical parameter:

Model

HC-180SP

HC-240SP Type of Pouch

Corner Spouted Stand Pouch Min. Pouch Size

90×120mm 120×160mm Max. Pouch Size

180×250mm 240×320mm Packing Speed

<50 Pouch per min. Packing Station 2 2 Packing Range

Max 1000ml

Max 2000ml Power

10kw

15kw Volt

380V 3P 50Hz

Air Consumption

400L/min

500L/min Air Pressure

0.7MPa

0.7MPa Machine Weight

3000kg

3500kg Machine Dimension

7500*1500*1500mm

9000*1500*1500mm

Key words:

Key words:- spout doypack packing machine

- Corner Spouted Doypack Package Machine

- spout pouch packing machine

- spout packing machine

- standing pouch spout pack machine

- spout pouch linear filling machine

- doy pack spout pouch sealing machine

- spout pouch packing machine

Provide solutions for your industry and prepare for your choice

RECOMMENDED PRODUCTS

Liquid Rotary Premade Pouch Packing Machine

Rotary Premade Pouch Packing Machine is a type of packaging equipment used to automatically fill various products and seal pre-made pouches . Rotary packing machine features a rotary design, which allows for high-speed, efficient, and continuous packaging operations. Rotary pouch packing machine is commonly used in industries such as food, beverages, pharmaceuticals, and chemicals .

MORE +HC-240G/330G Horizontal Premade Pouch Packing Machine

This machine can realize the packaging of three-side seal .four-side seal ,hanging hole bag ,stand-up bag ,special-shaped bag and other bag types , which is suitable for the packaging needs of powders , granules, liquids, pastes, solids and other materials , and can also be customized according to customer needs .

MORE +HC-130/180 Horizontal Flat Bag Packing Machine For Powder/Granule/Liquid

The Grepack HC-130 is a fully automatic horizontal form-fill-seal (HFFS) packaging machine, designed for efficiently packaging free-flowing powders, granules, and other granular materials into 3/4 Side Seal Sachet

MORE +