Automatic Horizontal Premade Pouch Packing Machine (HFS Type)

Category:

Horizontal premade pouch packing machine for doypacks, zipper bags, and spout pouches. Ideal for packing powder, granules, and liquids with high flexibility.

- Product Description

-

- Commodity name: Automatic Horizontal Premade Pouch Packing Machine (HFS Type)

- Commodity ID: HC-240G

Horizontal premade pouch packing machine for doypacks, zipper bags, and spout pouches. Ideal for packing powder, granules, and liquids with high flexibility.

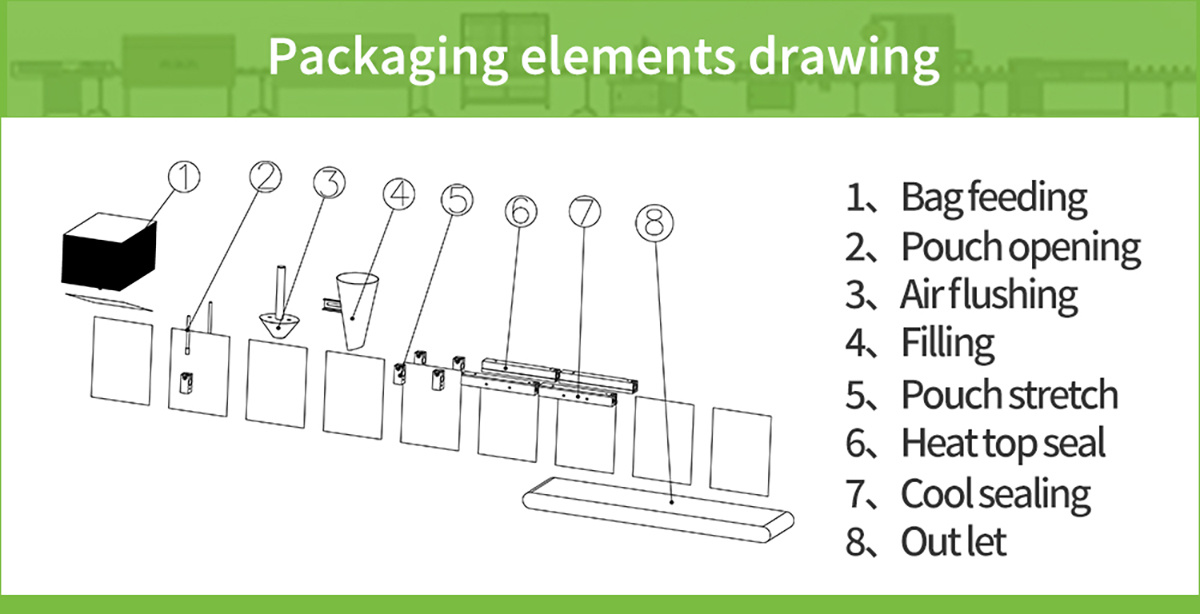

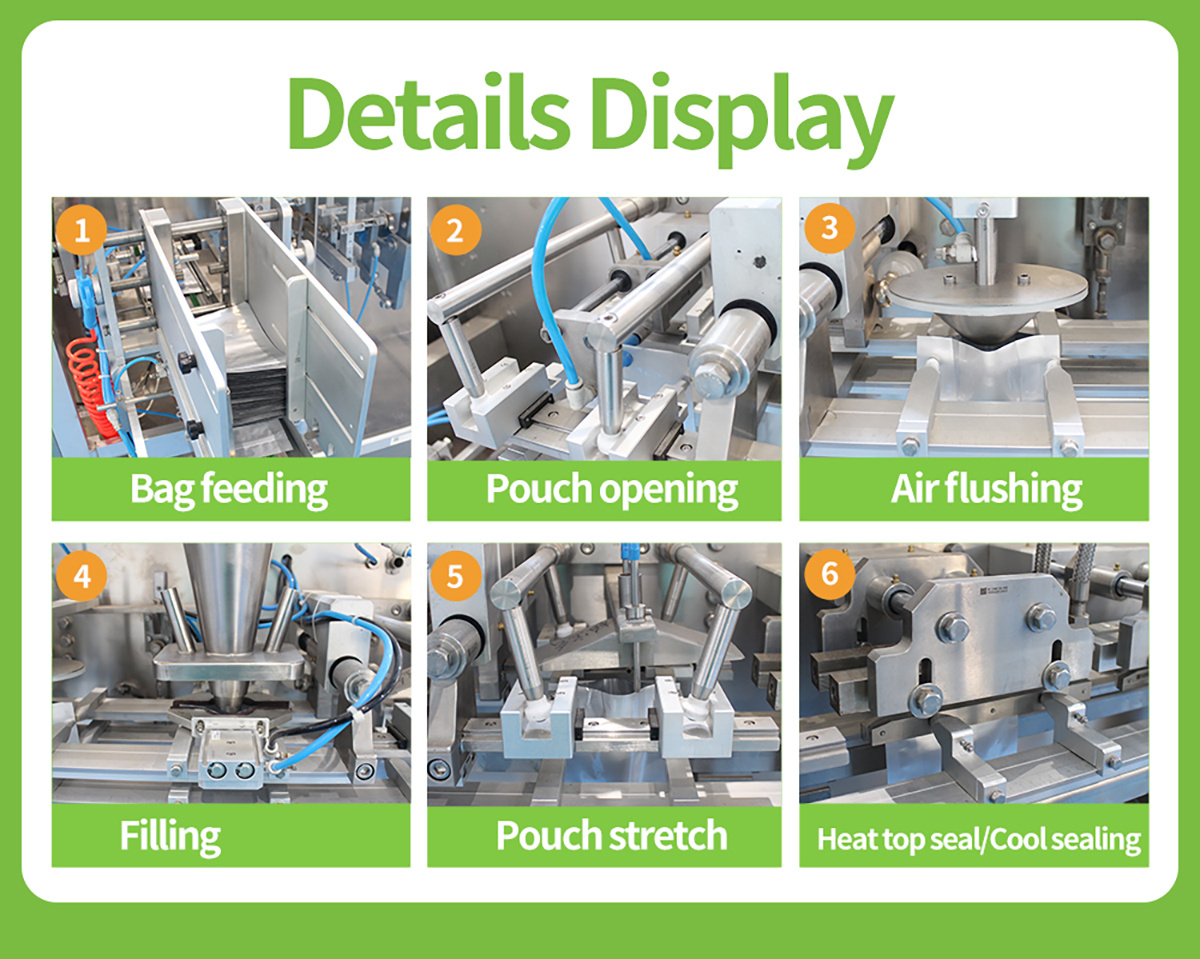

This Horizontal Form-Fill-Seal (HFS) Machine is a high-performance solution designed for handling pre-made pouches. Unlike rotary packers, the horizontal linear design allows for superior flexibility when handling larger bag sizes and heavier fill weights. It is the perfect "All-in-One" packaging solution for manufacturers who need to pack various products (Powder, Liquid, Granule) into premium pouch styles, such as Doypacks (Stand-up Pouches), Zipper Bags, and Spout Pouches.

Key Features (Why Choose Horizontal?):

✅ Multi-Pouch Versatility: One machine can handle almost all pouch types: Flat Sachet, Stand-up Pouch (Doypack), Zipper Pouch, Spout Pouch, and Shaped Pouch.

✅ Reliable Zipper Opening: Equipped with a specialized Zipper Opening Device that mechanically opens the zipper before filling. This ensures the product is filled deeply into the bag without contaminating the seal area.

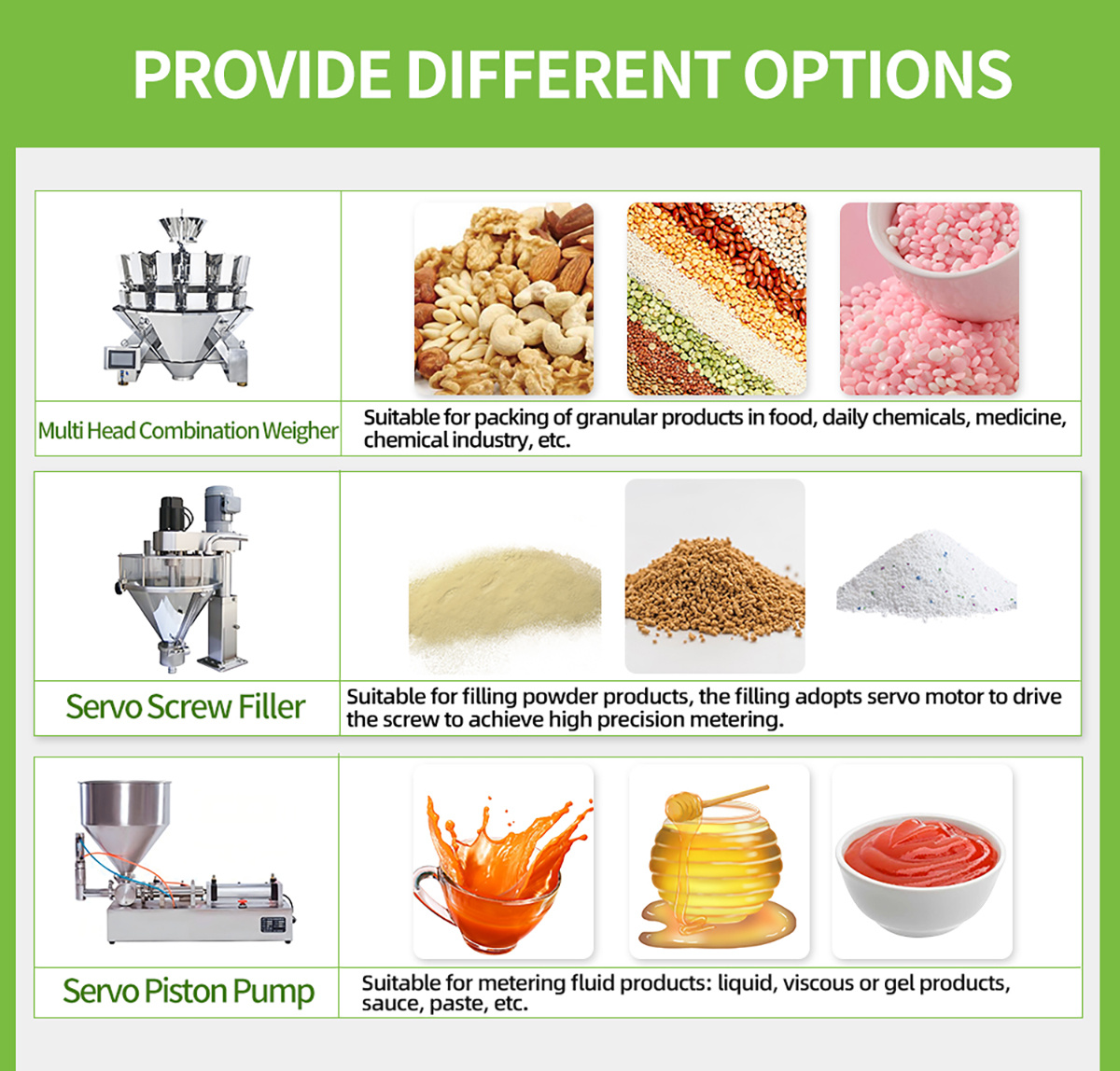

✅ Flexible Filling System: The machine features a modular filling station. You can easily swap between an Auger Filler (for powder), a Piston Filler (for liquid), or a Multi-head Weigher (for granules) depending on your production needs.

✅ Quick Size Changeover: Adjusting the bag width is simple via the hand-wheel or touch screen, making it ideal for factories that run multiple SKU sizes on a single line.

✅ Superior Sealing Quality: The horizontal flow provides stronger, flatter sealing pressure, ensuring airtight and leak-proof seals, which is critical for retort pouches or heavy liquid bags.

Applications (What can it pack?):

Liquids: Detergent, Liquid Soap, Sauce, Juice (Spout Pouch).

Powders: Coffee, Milk Powder, Spice, Protein Powder (Zipper Pouch).

Granules: Snacks, Pet Food, Candy, Nuts (Doypack).

Technical specifications:

Model HC-240G HC-330G Pouch Type 3/4 side seal/stand pouch/zipper pouch 3/4 side seal/stand pouch/zipper pouch Min Pouch 120×130mm 150×180mm Max Pouch 240×350mm 330×500mm Packing Speed < 60 pouch per min 15-30 pouch per min Packing Range Max. 1500ml Max. 2500ml Filling Station 1 1 Power 3.5KW 3.5KW Volt 380V 3P 50Hz 380V 3P 50Hz Air Consumption 300L/min 300L/min Air Pressure 0.7MPa 0.7MPa Machine Weight 1500kg 2000kg Machine Dimension 2735×1500×1420mm 3657×2160×1420mm

Key words:

Key words:- Premade pouch Packing Machine

- premade bag packing machine

- given bag packing machine

- premade bag packaging machine

- premade pouch filling machine

- premade pouch packing machine

- premade bag filling and sealing machine

- premade pouch packaging machine

- premade pouch fill and seal machine

- automatic premade pouch packing machine

Get Your Free Custom Packaging Solution & Quote

RECOMMENDED PRODUCTS

Automatic Rotary Spout Pouch Filling & Capping Machine

Rotary machine for filling and capping spout pouches. Suitable for juice, jelly, and detergent. Fills through the spout for a clean finish.

MORE +