Automatic Horizontal Labeling Machine for Cylindrical Products

Category:

- Product Description

-

- Commodity name: Automatic Horizontal Labeling Machine for Cylindrical Products

- Commodity ID: MPC-BS

The MPC-BS Series is a highly versatile Horizontal Labeling Machine designed for any cylindrical product with a small diameter that cannot stand upright on a conveyor belt. Whether it is glass, plastic, metal, or food material, as long as it is cylindrical, this machine can label it efficiently.

Key Features & Advantages

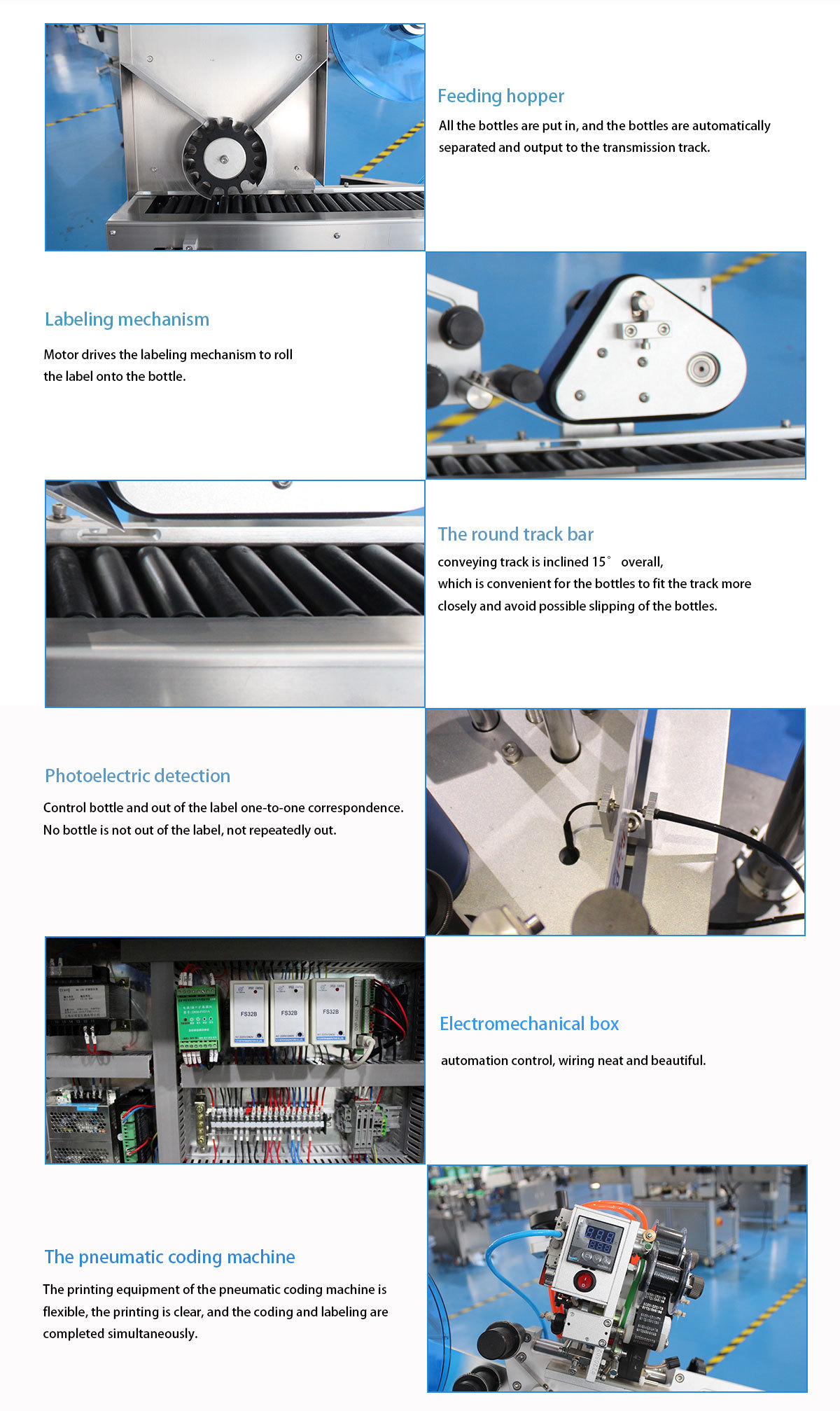

1. Universal Compatibility: One machine handles a wide variety of industries. It is easily adjustable to label products with diameters ranging from 10mm to 30mm (customizable for larger sizes).2. Horizontal Roller System: Adopts a specialized roller conveyor system that lays products down horizontally. This ensures stability for slender items that would otherwise fall over on a standard vertical labeler.

3. High Precision & Quality: Features a wrap-around rolling belt structure to ensure the label is applied smoothly around the cylinder without bubbles or wrinkles.

4. Intelligent Control: Powered by a PLC system with a Touch Screen. You can save parameter settings for different products (e.g., switch from labeling "Batteries" to "Lipsticks" quickly).

Wide Application Range (Examples)

This machine is suitable for labeling almost all cylindrical objects, including but not limited to:Stationery: Marker pens, Glue sticks, Crayons.

Hardware & Electronics: AA/AAA Batteries, Capacitors, Cartridges.

Food: Ham sausages, Candy rolls.

Cosmetics: Lipstick tubes, Eyeliner pencils, Lip balm, Mascara.

Medical: Vials, Ampoules, Syringes, Test tubes, Blood collection tubes.

Technical Parameters

Model MPC-BS Voltage

AC110V/220V 50/60HZ

Power

1 kw

Labeling Speed

10ml ampoules,the labeling speed is 150~250 bottles/min(speed adjustable)

Labeling Accuracy

+0.5mm

Bottle Height

Outer diameter 10mm~~24mm , Height 20mm~150mm(Customizable)

Label Specifications

Height 10mm~60mm Length 10mm~80mm

Paper Roll Size Inner diameter Φ76mm outer diameter Φ300(Maximum) Machine Weight

220kg

Machine Size

1800mmX600mmX1400mm

Key words:

Key words:- Horizontal labeling machine

- vial labeling machine

- tube labeling machine

- Labeling machine for cylindrical objects that are not easy to stand

- Pencil horizontal labeling machine

- Test tube labeling machine

Get Your Free Custom Packaging Solution & Quote

RECOMMENDED PRODUCTS

Automatic Double Side Labeling Machine (For Square & Flat Bottles)

Automatic labeling machine for applying front and back labels on square, flat, and oval bottles. Features a chain alignment system to ensure straight placement.

MORE +Automatic Wrap-Around Labeling Machine (360° Full Circle)

High-precision vertical labeling machine for round bottles. Capable of 360° full wrap labeling with perfect overlap. Ideal for vials and wine bottles.

MORE +Automatic Star Wheel Positioning Labeling Machine (Fixed-Point / Orientation)

Our cylindrical bottle labeling machine is purpose-built to solve high-volume labeling challenges for cylindrical objects across the pharmaceutical industry, daily chemical industry, and food industry. It specializes in automatic high-speed labeling—supporting both full-wrap (360°) and half-wrap labeling—and features an innovative astrolabe-turning structure that streamlines the workflow into three seamless steps: bottle in → label apply → bottle out. This design eliminates misalignment, reduces label waste, and significantly boosts the labeling pass rate.

MORE +