Automatic Liquid Detergent Bottle Filling Machine

Category:

This series of filling machines is suitable for filling materials with certain fluidities such as liquid, lotion, and paste; Such as care solutions, hair conditioner, hand sanitizer, shampoo, body lotion, shower gel, perfume, liquid foundation, disinfectant, gel, antifreeze, eye wash, and other liquid products.

- Product Description

-

- Commodity name: Automatic Liquid Detergent Bottle Filling Machine

- Commodity ID: GP Series

This series of filling machines is suitable for filling materials with certain fluidities such as liquid, lotion, and paste; Such as care solutions, hair conditioner, hand sanitizer, shampoo, body lotion, shower gel, perfume, liquid foundation, disinfectant, gel, antifreeze, eye wash, and other liquid products.

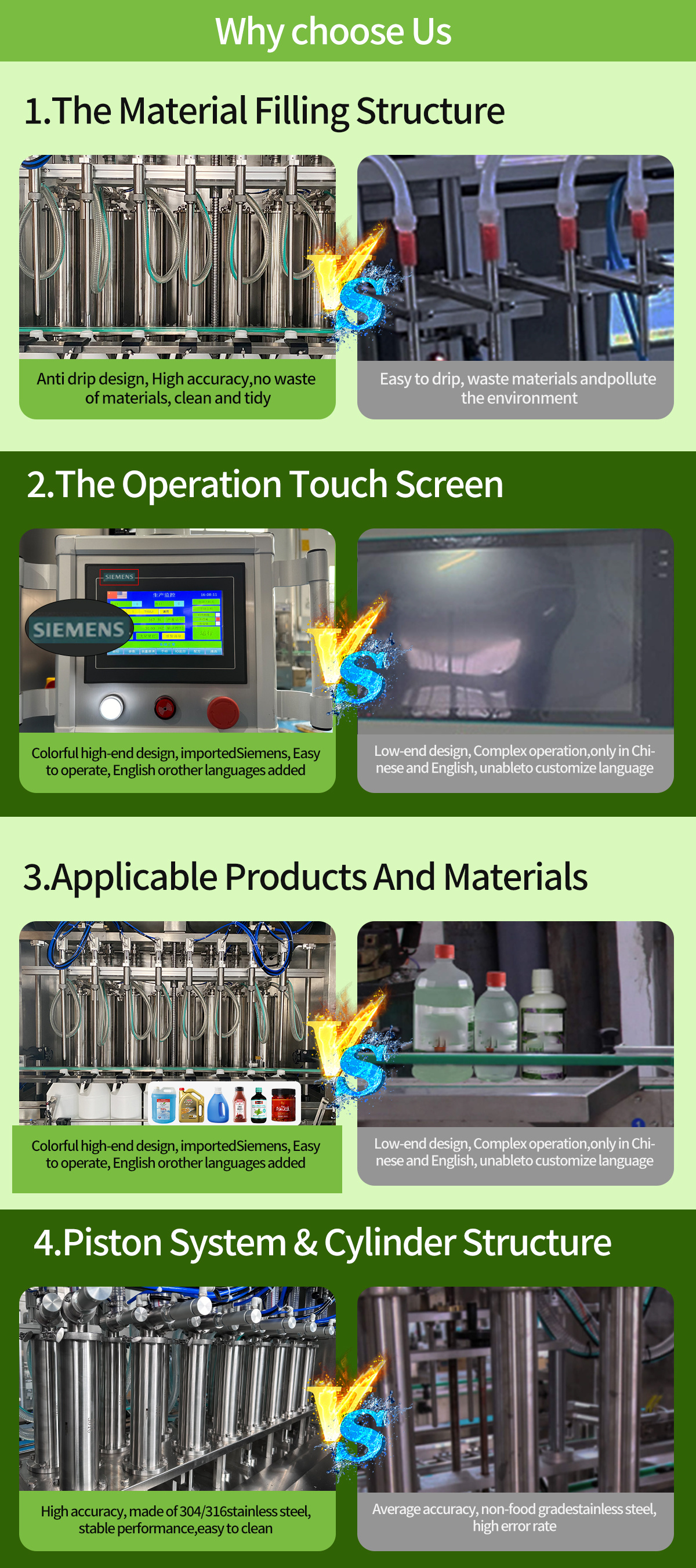

Automatic detergent filling machine is a kind of washing filling machine. It is an advanced filling equipment for hand soap and washing products according to the characteristics of hand soap, such as viscosity and slight corrosiveness. The filling plug with anti-dripping and wire drawing, and the filling lifting system with anti-high foam products.

Machine Features

1. Equipped with Siemens PLC and touch screen, ensuring stable and reliable performance.

2. The low-voltage electrical components adopt the Schneider brand.

3. The filling volume can be adjusted with one-click on the touch screen, and the data can be stored.

4 . The piston is driven by a servo motor, ensuring fast speed and high precision.

Technical parameter:

Model

GP125Series/GP500Series/GP1000Series/GP3000Series/GP5000Series Filling Range

30-125ml,50-500ml,100-1000ml,500-3000ml,1000-5000ml Filling Nozzle

4

6

8

10

12

Filling Capacity

(Based on 1000ml)≤ 1200BPH ≤ 1800 BPH

≤2400 BPH

≤3000 BPH

≤3600 BPH

Filling Accuracy

≤±0.5%

Voltage

AC220V/380V 50-60HZ (Special customizable)

Power

2.0-3.5KW

2.0-4.0KW

2.5-4.5KW

3.0-5.5KW

3.0-6.5KW

Air Pressure

0.5-0.8Mpa

Our factory located workshop over 8000 square meters, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solutions!

Our factory located workshop over 8000 square meters, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solutions!

The company is well-equipped, strong technical strength, has a professional and efficient R & D team, the enterprise internal management is tight, products from production to after-sales service, "Grepack people" in line with the "innovation, professional, cooperation, win-win" core values, adhere to the "quality first, customer first" business policy; The pursuit of "improve product quality, adhere to innovation" as our goal; Truly achieve "customers, enterprises, employees win-win". Key words:

Key words:- detergent filling machine

- Shampoo Filling Machine

- Piston Filling Machine

- detergent bottle filling machine

- liquid soap filling machine

- piston filling machine

- dishwashing filling machine

- laundry detergent filling machine

Get Your Free Custom Packaging Solution & Quote

RECOMMENDED PRODUCTS

High-Speed Automatic Tracking Filling Machine

High-speed tracking filling machine where nozzles move with bottles for non-stop production. Ideal for foamy detergents and shampoos. Speed: up to 8000 BPH.

MORE +Automatic Weight Filling Machine (Weighing Type for 5kg-50kg)

Automatic Net Weight Filler for 5kg-50kg containers. Uses high-precision Load Cells to control filling quantity. Ideal for Oil and Chemicals.

MORE +Automatic Anti-Corrosive Liquid Filling Machine (For Strong Acids & Bleach)

Heavy-duty filling machine constructed from PP/PVC for strong acids, bleach, and toilet cleaners. Features 100% metal-free liquid contact parts to ensure a long lifespan in corrosive environments.

MORE +