Automatic Sauce/Paste Bottle Filling Machine

Category:

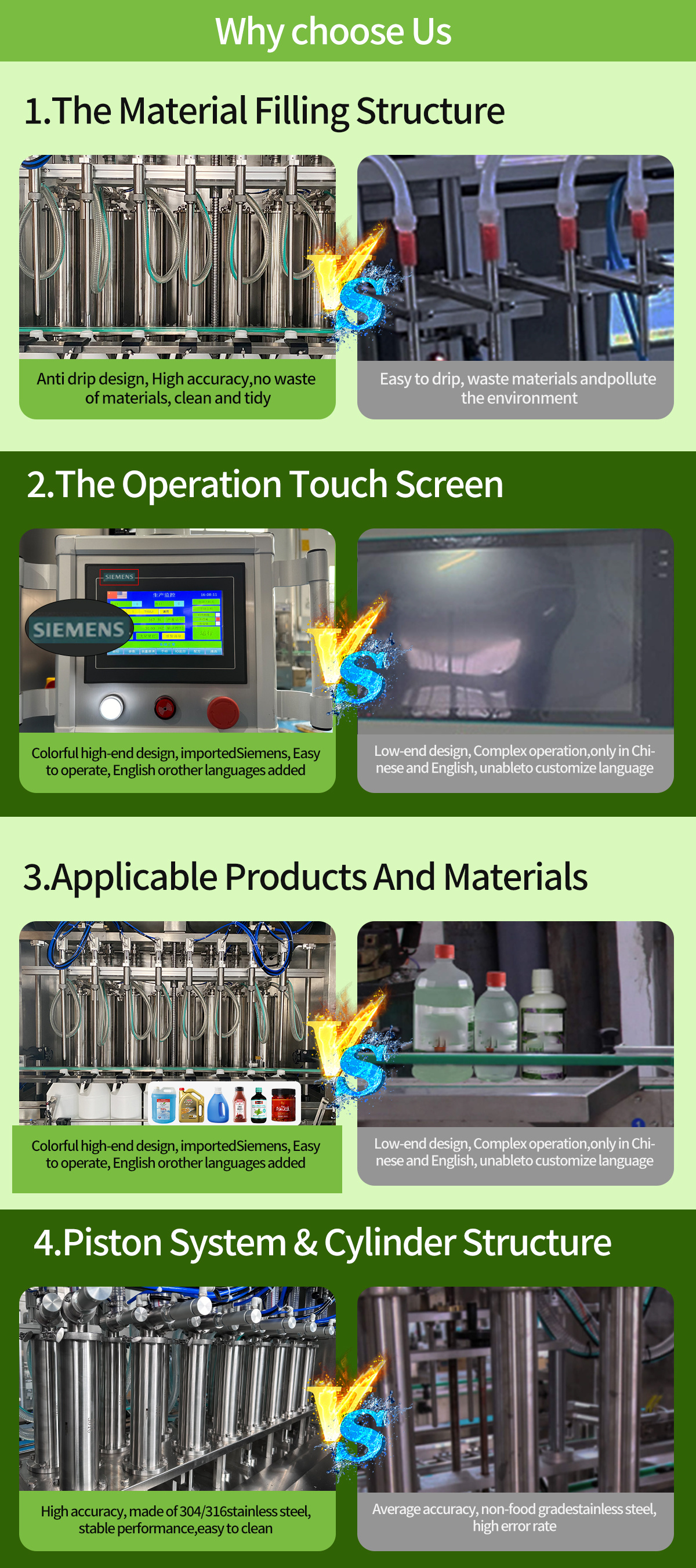

Designed for High Viscosity & Paste Products. The Grepack Automatic Piston Filling Machine is the ideal solution for thick liquids like Ketchup, Honey, Jam, and Creams. ✅ High Precision: Servo motor driven piston ensures filling accuracy ±1%. ✅ No Drip: Special anti-drop nozzles keep your bottles and conveyor clean. ✅ Easy Clean: Quick-release structure, food-grade SS304/316 material. ✅ Versatile: Suitable for glass jars, PET bottles, and metal cans.

- Product Description

-

- Commodity name: Automatic Sauce/Paste Bottle Filling Machine

- Commodity ID: GP125

Designed for High Viscosity & Paste Products. The Grepack Automatic Piston Filling Machine is the ideal solution for thick liquids like Ketchup, Honey, Jam, and Creams. ✅ High Precision: Servo motor driven piston ensures filling accuracy ±1%. ✅ No Drip: Special anti-drop nozzles keep your bottles and conveyor clean. ✅ Easy Clean: Quick-release structure, food-grade SS304/316 material. ✅ Versatile: Suitable for glass jars, PET bottles, and metal cans.

This machine is Grepack's specialized solution for the Food & Condiment Industry. It is engineered to handle thick, viscous, and semi-solid products, even those containing particles or chunks (such as chili seeds in hot sauce or fruit chunks in jam). Unlike standard liquid fillers, this machine utilizes a powerful Servo Piston system combined with a specialized Rotary Valve design to ensure smooth flow without clogging, maintaining the texture and integrity of your delicious sauce.

Key Features (Why Choose This for Sauce?):✅ Handles Particulates (Rotary Valve): The core advantage of this machine is the Rotary Valve System (instead of a standard check valve). It opens a wide path for the sauce, allowing particles, seeds, and fruit chunks to pass through easily without blocking the nozzle.

✅ Heated Hopper with Mixer (Agitator): Thick sauces (like peanut butter or chocolate) can become hard when cold. Our machine comes with a Double-Jacketed Hopper that can heat the product and a Stirring Agitator to keep the sauce uniform and flowable.

✅ High Temperature Filling: Designed to withstand high temperatures, making it suitable for "Hot Filling" processes (up to 80°C - 95°C) often required for jams and tomato pastes to ensure

✅ Servo Precision: Driven by high-torque Servo Motors, ensuring precise weight control for every bottle, reducing the waste of expensive food ingredients.

✅ Food Safety (CIP): All contact parts are made of Food Grade SUS304/316L Stainless Steel. The quick-release structure supports fast disassembly for deep cleaning, preventing cross-contamination between different sauce flavors.

Applications (What can it fill?):

Smooth Sauces: Ketchup, Mayonnaise, Tomato Paste, Mustard, Honey.

Chunky Sauces: Chili Sauce (with seeds), XO Sauce, Fruit Jam (with pulp), Salad Dressing.

Thick Pastes: Peanut Butter, Chocolate Spread, Tahini.

Technical parameter

Model GP125Series/GP500Series/GP1000Series/GP3000Series/GP5000Series Filling Nozzle 4 6 8 10 12 Filling Range 30-125ml,50-500ml,100-1000ml,500-3000ml,1000-5000ml Filling Capacity

(Based on 1000ml)≤ 1200BPH ≤ 1800BPH ≤2400BPH ≤3000BPH ≤3600BPH Filling Accuracy ≤±0.5% Voltage AC220V/380V 50-60HZ (Special customizable) Air Pressure 0.5-0.8Mpa Power 2.0-3.5KW 2.0-4.0KW 2.5-4.5KW 3.0-5.5KW 3.0-6.5KW

Our factory located workshop over 8000 square meters, with 20 engineers at design & installation work, over 100 employees for service support, Grepack provides clients the flexible and suitable packing solutions!

The company is well-equipped, strong technical strength, has a professional and efficient R & D team, the enterprise internal management is tight, products from production to after-sales service, "Grepack people" in line with the "innovation, professional, cooperation, win-win" core values, adhere to the "quality first, customer first" business policy; The pursuit of "improve product quality, adhere to innovation" as our goal; Truly achieve "customers, enterprises, employees win-win". Key words:

Key words:- Sauce Filling Machine

- Automatic filling machine

- Sauce Bottle Filling Machine

- Ketchup Filling Machine

- Peanut Butter Filling Machine

- Chocolate Sauce Filling Machine

- Jam Filling Machine

- Chili sauce filling machine

- Mayonnaise filling machine

Get Your Free Custom Packaging Solution & Quote

RECOMMENDED PRODUCTS

Automatic Edible Oil Filling Machine (Servo Piston Type)

High-accuracy servo piston filler for cooking oils like sunflower, corn, and olive oil. Features food-grade materials and specialized non-drip nozzles.

MORE +The sauce filling line is innovatively designed, which has the advantages of simple structure, high accuracy, and convenient operation, and is

MORE +High-Speed Automatic Tracking Filling Machine

High-speed tracking filling machine where nozzles move with bottles for non-stop production. Ideal for foamy detergents and shampoos. Speed: up to 8000 BPH.

MORE +This machine is developed and designed for automatic powder canning machine, which is mainly aimed at ultra-fine powder which is easy to raise dust and high-precision filling requirements.

MORE +