- Product Description

-

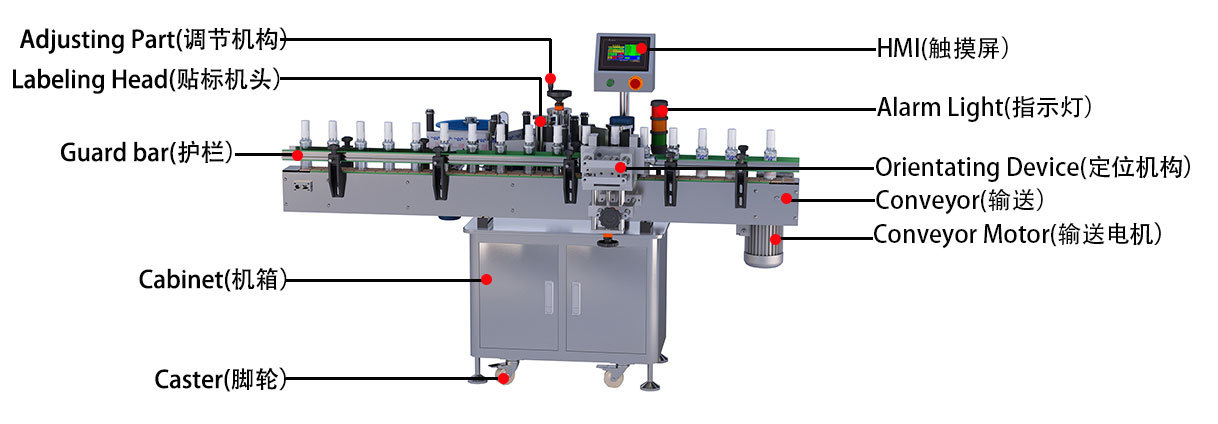

- Commodity name: Warp Around Labeling Machine

- Commodity ID: MPC-DW

Industrial Round Bottle Wrap-Around Labeling Machine: 360° Precise Labeling for Food, Beverage & Cosmetics Industries

Our round bottle wrap-around labeling machine is engineered to solve automatic labeling challenges for different-sized circular products across core sectors—including the food industry, beverage industry, and cosmetics industry. It integrates a professional fixed-point positioning mechanism to eliminate manual errors, boost production efficiency, and ensure consistent, high-quality labeling results, making it an ideal choice for both small-batch customization and large-scale mass production.Technical Parameters

Model MPC-DW Voltage

AC110V/220V 50/60HZ

Power

1.5kw

Labeling Speed

30~50 bottles/min (speed adjustable, depending on the size of the object and the length of the label)

Labeling accuracy

±0.5mm(Depends on product characteristics, softness and roundness)

Bottle Height

Height 40mm~300mm(Can be customized according to customer requirements)

Label Specifications

Height 20mm~200mm Lenght 20~200mm(Special specifications can be customized)

Paper Roll Size

Inner diameter Φ76mm outer diameter Φ300(Max.)

Machine Weight

200KG

Machine Size

2000mm×1000mm×1400mm

Air Pressure

0.6-0.8 Mpa

Key words:

Key words:- positioning labeling machine

- warp around labeling machine

- round bottle labeling machine

Previous

Previous

Provide solutions for your industry and prepare for your choice

RECOMMENDED PRODUCTS

This machine is suitable for labeling cylindrical products in food, daily chemical, chemical, pharmaceutical and other industries

MORE +Square Bottle Labeling Machine

This series of products is suitable for food, cosmetics, health care products, edible oil, daily necessities and other industries. For different sizes of square, flat, tapered, cylindrical and other bottle shapes, it can complete single-sided and double-sided labeling of products.

MORE +Star Wheel Warp Labeling Machine

Our cylindrical bottle labeling machine is purpose-built to solve high-volume labeling challenges for cylindrical objects across the pharmaceutical industry, daily chemical industry, and food industry. It specializes in automatic high-speed labeling—supporting both full-wrap (360°) and half-wrap labeling—and features an innovative astrolabe-turning structure that streamlines the workflow into three seamless steps: bottle in → label apply → bottle out. This design eliminates misalignment, reduces label waste, and significantly boosts the labeling pass rate.

MORE +