- Product Description

-

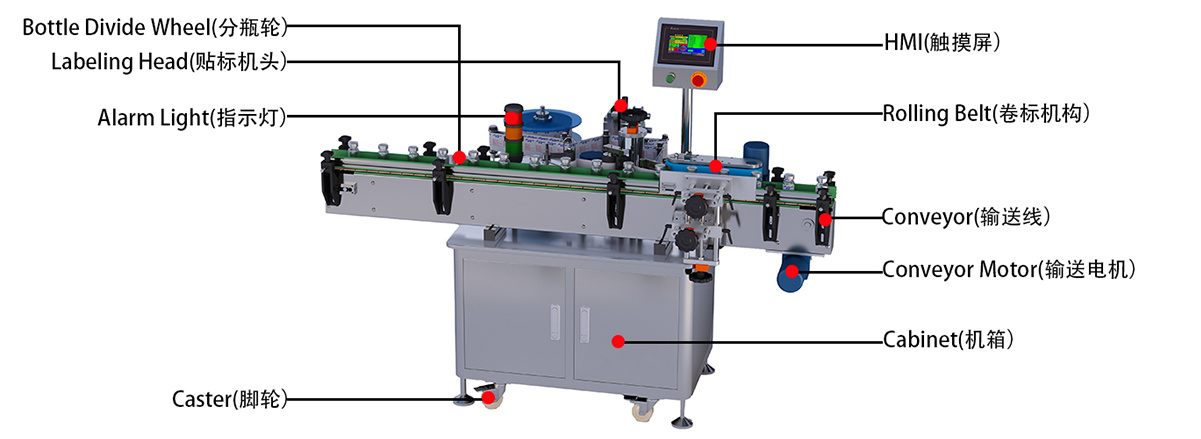

- Commodity name: Automatic Vertical Round Bottle Sticker Labeling Machine

- Commodity ID: MPC-AS

This machine is designed for the automatic application of self-adhesive labels on the curved surface of round bottles. It is widely used in food, medicine, and daily chemical industries for partial labeling or single-label applications.

Key Features & Advantages:

Stable Vertical Labeling: Adopts a standard synchronous chain and vertical guide mechanism to ensure the bottle remains stable during transport and labeling. Ideal for segment labeling on jars, vials, and bottles.

High Compatibility & Easy Adjustment: Suitable for a wide range of container diameters (φ30mm - φ100mm). The adjustment hand-wheel allows for quick setup when switching between different bottle sizes, saving production time.

Smart Label Detection: Equipped with high-sensitivity optical sensors (Magic Eye) to ensure the label is dispensed accurately every time. (Optional ultrasonic sensor available for transparent labels).

Cost-Effective Solution: A perfect choice for small to medium-scale production lines requiring reliable labeling performance without the complexity of high-speed rotary systems.

Optional Coder: Can be integrated with a batch number printer (Ribbon coder) to print dates on the label instantly.

The main technical parameters:

Model MPC-AS Voltage

AC110V/220V 50/60HZ

Power

1.2 KW

Labeling Speed

60-100 Bottle/Min(speed adjustable, depending on the size of the object and the length of the label)

Labeling Accuracy

±1mm(depending on product characteristics, hardness and roundness)

Bottle Height

Height 40mm~250mm(Can be customized according to customer requirements)

Label Specifications

Height 10~150mm Lenght 15mm~300mm (can be customized)

Paper Roll Size

Inner diameter Φ76mm Outer diameter Φ300mm(maximum)

Machine Weight

180KG

Machine Zize

2000mm*1000mm*1400mm (larger) 1800mm*1000mm*1400mm(small)

Key words:

Key words:- Round bottle labeling machine

- self-adhesive labeling machine

- Bottle labeling machine

- sticker labeling machine

- vertical round bottle labeling machine

Get Your Free Custom Packaging Solution & Quote

RECOMMENDED PRODUCTS

Automatic Double Side Labeling Machine (For Square & Flat Bottles)

Automatic labeling machine for applying front and back labels on square, flat, and oval bottles. Features a chain alignment system to ensure straight placement.

MORE +Automatic Wrap-Around Labeling Machine (360° Full Circle)

High-precision vertical labeling machine for round bottles. Capable of 360° full wrap labeling with perfect overlap. Ideal for vials and wine bottles.

MORE +Automatic Star Wheel Positioning Labeling Machine (Fixed-Point / Orientation)

Our cylindrical bottle labeling machine is purpose-built to solve high-volume labeling challenges for cylindrical objects across the pharmaceutical industry, daily chemical industry, and food industry. It specializes in automatic high-speed labeling—supporting both full-wrap (360°) and half-wrap labeling—and features an innovative astrolabe-turning structure that streamlines the workflow into three seamless steps: bottle in → label apply → bottle out. This design eliminates misalignment, reduces label waste, and significantly boosts the labeling pass rate.

MORE +